Ethanol: production, recovery and uses

CONTENTS

- Introduction

- Microorganisms

- Media

- Fermentation

- Recovery

INTRODUCTION

- Ethanol (also called ethyl alcohol, grain alcohol) is a chemical compound.

- The chemical formula is C2H5OH.

- Ethanol is volatile, flammable, colorless, liquid with slight characteristics odor.

- After 1906, when the industrial alcohol act was passed, the production of industrial alcohol become commercially feasible.

MICROORGANISMS

- The choice of fermentation organism for industrial alcohol production depends to some extent, on the type of carbohydrate present in the medium.

- Bacteria: clostridium, Zymomonas mobilis.

- Yeast: cerevisiae, candida spp.

- Filamentous fungi: Fusarium, Mucor sp.

- Starch and sugar raw material: Specially selected strains of Saccharomyces cerevisiae is used.

Strain selection

- Must grow rapidly and tolerant to high concentration of sugar.

- Must produce large amount of alcohol.

- Relatively resistant to alcohol.

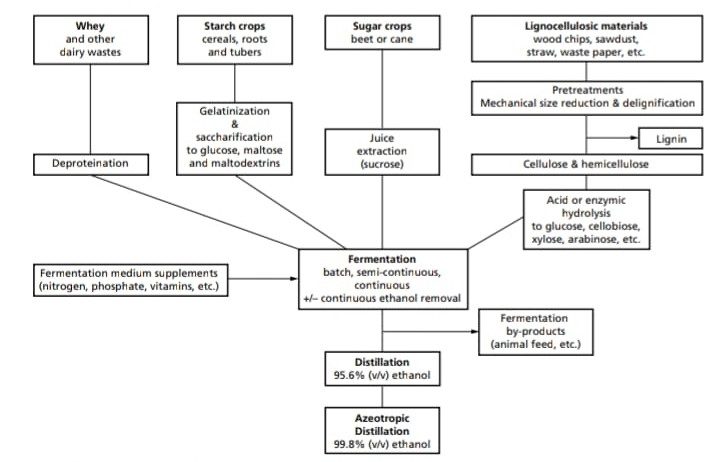

MEDIA

The principal media for the commercial production of industrial alcohol are:

- Blackstrap molasses or corn.

- Grains.

- Sulfite waste liquor.

- Whey potatoes.

- Wood waste.

- Sugarcane or sugar beet.

Fermentation

- Industrial alcohol production is carried out in very large fermenters (up to 125,000 gallons) and inoculum for these fermenters is added in the 3 to 10%.

- Temperature of fermenters is initially between 21° to 27°C but fermentation raises the temperature 28 to 30°C.

- Fermentation lasts approx. 2 to 3 days.

- Yeast cells are highly aerated to provide rapid cell multiplication.

- pH of the media ranges from 4.0 to 5.0 was the optimal for fermentations.

- The fermentation broth at completion of the fermentation contains in the range of 6 to 9% alcohol by volume and based on various reports, this alcohol yields reflects 90 to 98% theoretical conversion of substrate sugar to alcohol.

RECOVERY

Ethanol recovery is based on distillation:

-

- The broth is distilled in a beer column to harvest 85% v/v ethanol.

- The another step of rectification gives 96.5% ethanol, which is then, Dehydrated to 99.4% by using benzene or cyclohexane if the ethanol is to be used as a fuel blend.

- To obtain 100% it requires to form an azeotrophic mixture containing 5% water, thus 5% water is removed from mixture of ethanol water and benzene after distillation azeotrophic.

- In this process, benzene, water, ethanol and then ethanol benzene, azeotrophic mixtures to be removed, so that absolute alcohol is obtained.

USES

- Antiseptics: ethanol has a bactericidal and antifungal activity so, it commonly used in antibacterial hand sanitizer and as a antiseptics and disinfectants.

- Antidote: It is also administered as an antidote to different poisoning such as methanol, isopropyl alcohol and ethylene glycol.

- Fuel: it is largely used as an engine fuel and fuel additive.

- Rocket fuel: it was used as fuel in liquid propelled vehicle.

- Solvent: it is considered universal solvent because it allows dissolving of both polar, hydrophilic and non polar, hydrophobic.

- Ethanol is commonly and largely used as beverages for drinking purpose as well as in paints, tincture, etc.

- Also used as medical solvent.

Also Read:

- Beer brewing process

- Microbial Fuel Cells

- Electrophoresis: Overview, Principles and Types

- Citric acid: Introduction, Fermentation, Recovery and Uses

- Cider: Production, Extraction, Fermentation and Maturation

- Malaria: Causative Agent, Symptoms, Treatment and Prevention

- Gonorrhea: Causative Agent, Symptoms, Treatment and Prevention

- Reverse Transcription Polymerase Chain Reaction (RT-PCR)

- Comparison Between the Domains Bacteria, Archaea, and Eukarya

- Fundamental Principle of Clinical Specimen Collection

- Microbial Identification and Strain Typing Using Molecular Techniques