Penicillin: History, Structure, Production & Recovery

Content

- Introduction

- History

- Structure

- Penicillin molecule and its precussor

- Penicillinase

- 6- amino penicillanic acid

- Penicillin production

Introduction

- 1st antibiotic to be produced and still one of the best antibiotic available.

- Penicillin is a group of antibiotics, isolated from common molds known as Penicillium Molds.

- It is active against many gram-positive bacteria, Nocardia, Actinomycetes.

- It generally, interferes with cell wall synthesis of organisms which is sensitive and it is active only against vegetative cell.

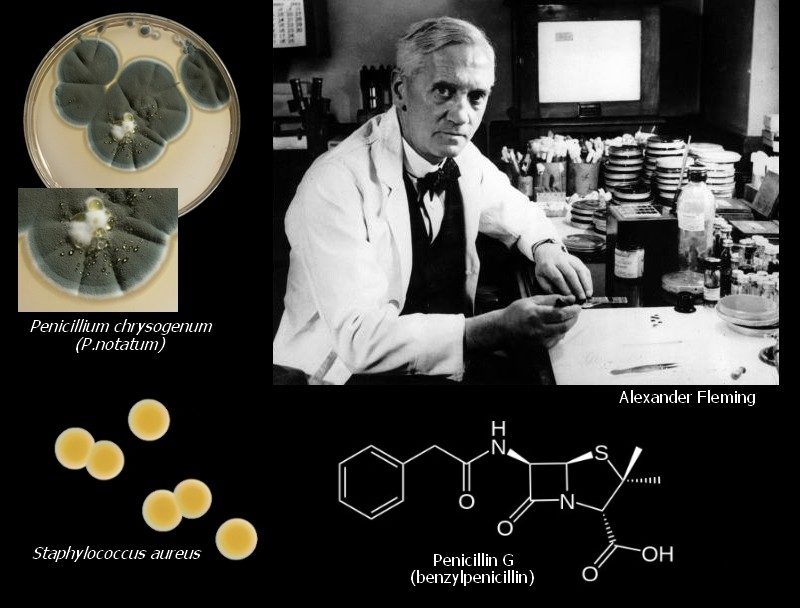

History

- Sir, Alexander Fleming in 1929, first observed the antibiotic properties and possible therapeutics value of penicillin.

- He observed that an airborne contaminant, later shown to be Penicillium notatum inhibited the growth of a culture of Staphylococcus aureus on agar medium in the area surrounding the fungal activity.

- Fleming further showed that this inhibitory effect Caused by a soluble, diffusible mold product.

- Penicillin observed by Fleming was Penicillin-G.

Structure

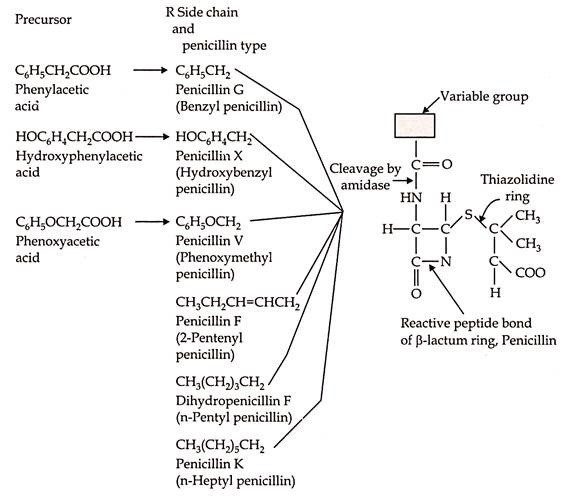

- Several penicillins are closely related in structure.

- Common chemical nucleus and a side chain attached to this nucleus.

- Various compounds resembling the side chain can be added as precursor to fermentation medium & through microbial strain are directly incorporated into Penicillin molecule.

- Fungi: Aspergillus & Penicillium.

- Various penicillin differs as nature of their “R’’ side chain.

Penicillin molecule and its Precursor

- Whereas, in present day commercial terms penicillin is regarded as the Penicillin-G.

- The Penicillin nucleus consists of two amino acids, L-cysteine and D-valine.

Penicillinase

- Penicillinase is an extracellular enzyme adaptively produced by members of the coliform group of bacteria, by most Bacillus sp.

- Major factor for penicillin resistance during infection.

- This enzyme hydrolyses penicillin to penicilloic acid.

6-amino penicillanic acid

- Sensitive to Penicillinase enzyme.

- Can be recovered from fermentation broth.

- Chemically converted to penicillin by chemical addition of various R side chains. Yield of this material is low.

- Penicillin acylase enzyme cleaves side chains of penicillin so resulted in commercial production 6-Amino penicillanic acid.

Penicillin production

- Commercially, penicillin was first produced in stationary mat culture.

- Production of penicillin is previously achieved by surface process i.e. solid-state fermentations and surface liquid fermentation.

Penicillin production mainly consists of three steps:

-

- Inoculum preparation

- Production fermentation

- Product recovery

Inoculum preparation

- Inoculum: Penicillium chrysogenum.

- For inoculum production, spores from heavily sporulated working stocks (special agar sporulation) are suspended in water or in a dilute solution of a nontoxic wetting agent, such as 1:10,000 sodium lauryl sulfonate.

- These spores are then poured in the flask which contains wheat bran and nutrient solution for heavy sporulation.

- Incubate for at 24°C for 5-7 days to provide heavy sporulation.

- Resulting spores are directly inoculated into inoculation tanks.

- Incubated at 25 to 26°C for 3 to 5 days exact duration of fermentation depends on various factors.

Production fermentation

- Method: fed batch or batch.

- Media: (Jackson 1958)

- Corn steep liquor solids-3.5%

- Lactose: 3.5%

- Cellulose: 1%

- CaCO3: 1%

- K2HPO4: 0.4%

- Edible oil: 0.25%

- Fermenter: stirred tank or air lift tank.

- Temperature: 25-27°C.

- Aeration: 0.5 – 27 1 VVM.

- Anti-foam: edible oil

- pH: set at 5.5 to 6.0 which increased up to 7-7.5.

- Inoculum media is same as production media.

- Lactose precursor is not added, at start of fermentation.

- PH remain constant, glucose, corn steep liquor, Carbon compounds and ammonia are utilised.

- Carbon compounds depleted, pH rise to 7-7.5.

- At the end of fermentation pH rises to 8 higher because depletion of lactose brings an autolysis in mycelium.

- Penicillium is harvested before this.

Product Recovery

- Harvest broth from fermenter tank by filtration.

- Chill to 5-10°C.

- Acidify filtrate to pH 2.0 to 2.5 with H2SO4.

- Penicillin extracted from aqueous filtrate into butyl acetate or amyl acetate.

- Discard aqueous fraction

- Add potassium acetate to the solvent extract in a crystallization tank to crystallize as potassium salt.

- Recover crystal from centrifuge.

- Further processing.

- Packaging.

Reference and Sources

- 1% – https://www.slideshare.net/guest08f61f/project-antibioticsbyharkiran-presentation

- 1% – https://quizlet.com/182638247/microbiology-iclicker-smartwork5-quiz-1-flash-cards/

- 1% – https://www.researchgate.net/publication/11010850_Optimization_of_a_fermentation_m

edium_for_the_production_of_Penicillin_G_acylase_from_Bacillus_sp - 1% – https://mafiadoc.com/download/practical-fermentation-technology_59da452a1723dd5e

e2b54f83.html

Also read:

- Ethanol : production, recovery and uses

- Microbiology Disciplines: Bacteria, Viruses, Fungi, Archaea and Protists

- Antimicrobial Chemotherapy: History, Characteristics and Tests

- Citric acid: Introduction, Fermentation, Recovery and Uses

- Streptomycin : chemical structure, production , recovery and uses.

Kindly send the brief notes for penicillin production