Overview of bioreactor or fermenters

Contents

- Introduction

- History

- Function

- Design

- Classifications

Introduction

- It is a device or system that used to support biologically active environment.

- It is a system within which substrate of very low value is employ by living cells or enzymes to produce a product of greater value.

- A fermenter is a closed system vessel which have an adequate provision for temperature, agitation, aeration, pH control, and drain or overflow vent to remove waste biomass of culture microorganism with their products.

History

- In 1944 De becze and Liebmann used the primary large-scale fermenter for the growth of yeast.

- But, during the time of world war there’s is a British scientist whose name is Chain Weizmann who desigined a fermenter for the production of acetone.

Functions

- It should have a provision to control environment for optimum biomass or product yield.

- It should provide an aseptic fermentation condition for more reliablity.

- It should provide the adequate or proper mixing and aeration for the growth and production without damaging of the microorganisms or cells.

- It should have a system temperature control.

- It should have a system to monitor and regulate pH of the fermentation broth.

- Facility for sampling should be provided.

- It should have required minimum of labour in maintenance, cleaning, operating and harvesting operation.

Design

A bioreactor should consist of the followings:

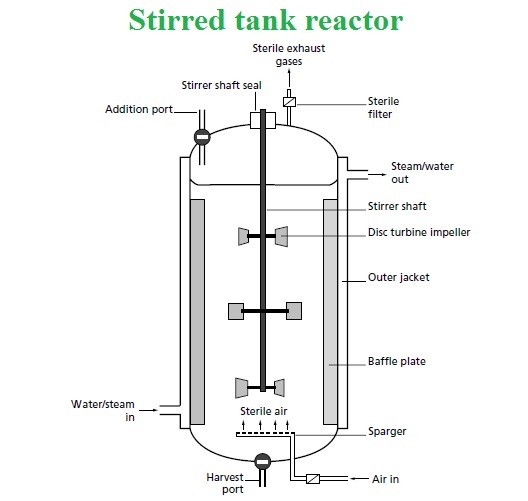

- Agitation- for mixing of cells and medium.

- Aeration – aerobic fermentation used for oxygen supply.

- Temperature

- pH, pressure, nutrients feeding, etc.

- Sterilization and maintenance of sterility.

- Withdrawal of cells or media.

Agitation and Aeration

- Agitations are aims to ensure similar distribution of microorganisms and the nutrients in the broth.

- Aeration to provide microorganisms growing in submerged culture with adequate oxygen supply.

The following components of the fermenter which is required for aeration and agitation:

- Agitator (impellers)

- Stirrer glands and bearings

- Baffles

- Sparger (the Aeration system)

Agitator (Impellers)

- It is of several different type:

-

- Disc turbine

- Vaned disc turbine

- Open turbine

- Propeller

- It achieves the following objective:

- Bulk mixing

- Air dispersion

- Oxygen transfer

- Heat transfer

- Maintain uniform environment

Stirrer glands and bearings

- It provides for maintaining aseptic conditions over a long period.

Four basic types of seals used in fermenters are:

-

- Stuffing box

- Simple bush seal

- Mechanical seal

- Magnetic drive

Baffles

- It is metal strips.

- One tenth of the vessels diameter.

- Attached radially to fermenters wall.

- It provided to prevent vortex formation and improve efficiency.

Aeration system (Sparger)

- It introduces air into the fermenters broth.

It is of three types:

-

- Porous Sparger

- Orifice Sparger

- Nozzle Sparger

Temperature control: adequate provision for control of Temperature.

Pressure gauge: It measures pressure inside the fermenters.

pH probe: It provides to measure and monitor pH of the medium.

Inlet air filter: Provision to supply air in the fermenters.

Exhaust air filter: Provision to drain out the air from the fermenters.

Cooling jacket: Provided to maintain the temperature of the fermenters throughout the process.

Control panel: it monitors all the parameters.

Foam control: it is produced during most microbial fermentation. Antifoams are used to removes foam from the surface of media e.g., silicone, soybean oil, cotton seed oil, sulphonate etc.

Classifications

- On the basis of agent used, bioreactors are of two types:

-

- On the basis of living cells

- On the basis of enzymes employed

- In the terms of process fermenters, is of following types:

-

- Aerobic

- Anaerobic

- Solid state

- Immobilized cell disruption

Types of fermenters

- Fermenters are of 4 types:

-

- Stirred tank reactor

- Airlift fermenters

- Tower fermenters

- Bubble up fermenters

Stirred tank reactor

- Smaller vessel is made up of glass while, lager vessels are made up of stainless steel of 1-1,000 or even 8,000L.

- They are closed system in which volumes are fixed.

- They are agitated with motor driven stirrer’s.

- It is a kind reactor with continuous flow culture system which is either of chemostat or turbidostat type.

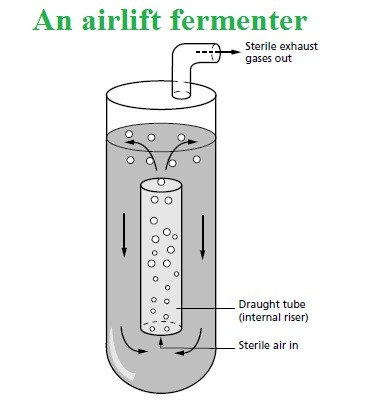

Airlift fermenters

- It comprises of a gas light baffled riser tube or drought tube which is connected to the downcomer tube.

It is of two types:

-

- Internal- loop airlift bioreactor

- External loop airlift bioreactor

- These type of fermenters are commonly employed for aerobic bioprocessing technology.

- Because of their high efficiency, it is mostly preferred for production of methanol and SCP, etc.

Tower fermentation

- It was defined by Greenshields and co-workers.

- It is an elongated non-mechanically type of fermenters.

- There is unidirectional gases flow throughout the bioreactors.

Tower fermenters are of following types:

-

- Bubble columns

- Vertical tower beer fermenters

- Multistage fermenters

Bubble up fermenters

- It is a bubble columns fermenters which havee an internal cooling coil.

- Air is introduced from the bottom of the column.

Reference and Sources

- 1% – https://wiki2.org/en/Bioreactor

- 1% – https://samacheerkalvi.guru/author/bhagya/page/9/

- 4% – https://www.slideshare.net/shmpanwar92/bioreactors-fermenters-56475754

- 2% – https://senthilarivan.wordpress.com/2015/11/26/fermenter-and-its-features/

- 1% – https://www.dedot.info/airlift-fermenters-17/

Also Read:

- Overview of Microbial Growth control

- Water as a Microbial Habitat

- Influence of Environmental Factors on Microbial Growth

- Endospore staining and capsule staining of the bacteria

- CRISPR-Cas9 Gene editing tool: Introduction, Principles, Uses & Applications