Introduction

A bioreactor (or fermenter) is a vessel or system designed to support biologically active environments, primarily used for growing organisms like bacteria, yeast, fungi, animal, or plant cells under controlled conditions. These devices are essential in biotechnology, pharmaceuticals, food processing, and industrial microbiology.

- It is a device or system that used to support biologically active environment.

- It is a system within which substrate of very low value is employ by living cells or enzymes to produce a product of greater value.

- A fermenter is a closed system vessel which have an adequate provision for temperature, agitation, aeration, pH control, and drain or overflow vent to remove waste biomass of culture microorganism with their products.

History

- In 1944 De becze and Liebmann used the primary large-scale fermenter for the growth of yeast.

- But, during the time of world war there’s is a British scientist whose name is Chain Weizmann who desigined a fermenter for the production of acetone.

Functions

- It should have a provision to control environment for optimum biomass or product yield.

- It should provide an aseptic fermentation condition for more reliablity.

- It should provide the adequate or proper mixing and aeration for the growth and production without damaging of the microorganisms or cells.

- It should have a system temperature control.

- It should have a system to monitor and regulate pH of the fermentation broth.

- Facility for sampling should be provided.

- It should have required minimum of labour in maintenance, cleaning, operating and harvesting operation.

Design

A bioreactor should consist of the followings:

- Agitation- for mixing of cells and medium.

- Aeration – aerobic fermentation used for oxygen supply.

- Temperature

- pH, pressure, nutrients feeding, etc.

- Sterilization and maintenance of sterility.

- Withdrawal of cells or media.

Agitation and Aeration

- Agitations are aims to ensure similar distribution of microorganisms and the nutrients in the broth.

- Aeration to provide microorganisms growing in submerged culture with adequate oxygen supply.

The following components of the fermenter which is required for aeration and agitation:

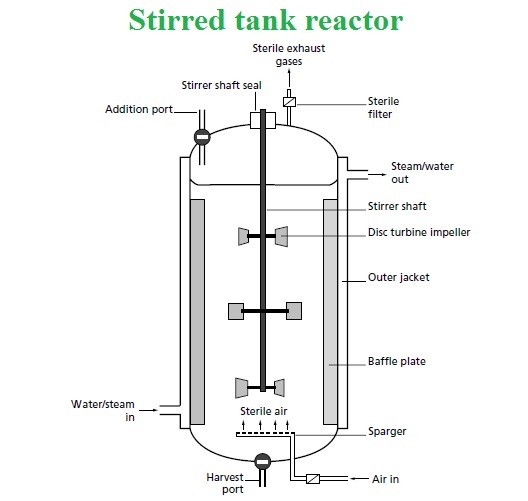

- Agitator (impellers)

- Stirrer glands and bearings

- Baffles

- Sparger (the Aeration system)

Agitator (Impellers)

- It is of several different type:

-

- Disc turbine

- Vaned disc turbine

- Open turbine

- Propeller

- It achieves the following objective:

- Bulk mixing

- Air dispersion

- Oxygen transfer

- Heat transfer

- Maintain uniform environment

Stirrer glands and bearings

- It provides for maintaining aseptic conditions over a long period.

Four basic types of seals used in fermenters are:

-

- Stuffing box

- Simple bush seal

- Mechanical seal

- Magnetic drive

Baffles

- It is metal strips.

- One tenth of the vessels diameter.

- Attached radially to fermenters wall.

- It provided to prevent vortex formation and improve efficiency.

Aeration system (Sparger)

- It introduces air into the fermenters broth.

- It is of three types:

-

- Porous Sparger

- Orifice Sparger

- Nozzle Sparger

- Temperature control: adequate provision for control of Temperature.

- Pressure gauge: It measures pressure inside the fermenters.

- pH probe: It provides to measure and monitor pH of the medium.

- Inlet air filter: Provision to supply air in the fermenters.

- Exhaust air filter: Provision to drain out the air from the fermenters.

- Cooling jacket: Provided to maintain the temperature of the fermenters throughout the process.

- Control panel: it monitors all the parameters.

- Foam control: it is produced during most microbial fermentation. Antifoams are used to removes foam from the surface of media e.g., silicone, soybean oil, cotton seed oil, sulphonate etc.

Classifications

- On the basis of agent used, bioreactors are of two types:

-

- On the basis of living cells

- On the basis of enzymes employed

- In the terms of process fermenters, is of following types:

-

- Aerobic

- Anaerobic

- Solid state

- Immobilized cell disruption

Types of fermenters

- Fermenters are of 4 types:

-

- Stirred tank reactor

- Airlift fermenters

- Tower fermenters

- Bubble up fermenters

Stirred tank reactor

- Smaller vessel is made up of glass while, lager vessels are made up of stainless steel of 1-1,000 or even 8,000L.

- They are closed system in which volumes are fixed.

- They are agitated with motor driven stirrer’s.

- It is a kind reactor with continuous flow culture system which is either of chemostat or turbidostat type.

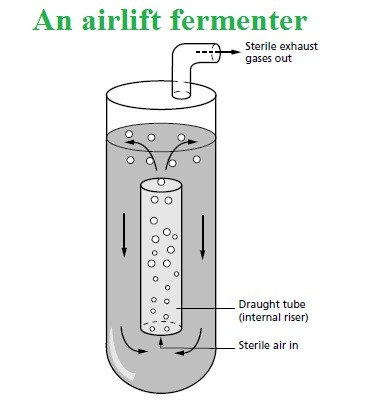

Airlift fermenters

- It comprises of a gas light baffled riser tube or drought tube which is connected to the downcomer tube.

It is of two types:

-

- Internal- loop airlift bioreactor

- External loop airlift bioreactor

- These type of fermenters are commonly employed for aerobic bioprocessing technology.

- Because of their high efficiency, it is mostly preferred for production of methanol and SCP, etc.

Tower fermentation

- It was defined by Greenshields and co-workers.

- It is an elongated non-mechanically type of fermenters.

- There is unidirectional gases flow throughout the bioreactors.

Tower fermenters are of following types:

-

- Bubble columns

- Vertical tower beer fermenters

- Multistage fermenters

Bubble up fermenters

- It is a bubble columns fermenters which havee an internal cooling coil.

- Air is introduced from the bottom of the column.

Reference and Sources

- 1% – https://wiki2.org/en/Bioreactor

- 1% – https://samacheerkalvi.guru/author/bhagya/page/9/

- 4% – https://www.slideshare.net/shmpanwar92/bioreactors-fermenters-56475754

- 2% – https://senthilarivan.wordpress.com/2015/11/26/fermenter-and-its-features/

- 1% – https://www.dedot.info/airlift-fermenters-17/

2 thoughts on “Overview of bioreactor or fermenters”

Great overview of bioreactors and fermenters! I appreciate the clear explanations and the emphasis on their roles in microbiology. It’s fascinating to see how these systems can optimize microbial processes for various applications. Looking forward to more insights!

Great overview of bioreactors and fermenters! I found the explanation of their roles in microbiology really insightful. It’s fascinating how these systems can be optimized for different microbial processes. Looking forward to more posts like this!