Streptomycin: Structure, Production, Recovery & Uses

Content

- Introduction

- Chemical structure

- Production

- Harvest and recovery

- Uses

Introduction

- Streptomycin is using for the treatment of no. of bacterial infection.

- Streptomycin is produced by Streptomyces griseus.

- It is particularly active against gram positive bacteria and against the tuberculosis organism Mycobacterium tuberculosis.

- Streptomycin was developed by Schatz Bugie and Waksman in 1944, and one of their original soil, S.griseus isolates was used today.

Chemical Structure

- Streptomycin and dihydrostreptomycin are basic compounds and therefore, they are usually prepared as salts.

- Streptomycin is present as the hydrochloride as crystalline HCl double salt with calcium chorial or as phosphate or sulfate and dihydrostreptomycin like hydrochloride or sulfate.

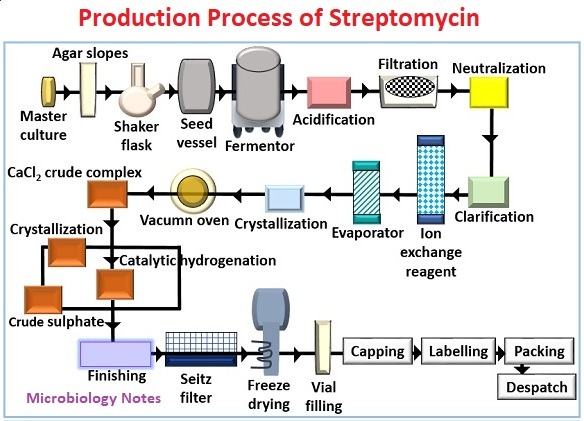

Production

Most of the media for the commercial yield of streptomycin are:

Woodruff and McDaniel (1954).

- Soybean- 1%

- Glucose -1%

- NaCl- 0.5%

Hockenhull -1963

- Glucose 2.5%

- Extracted soybean meal-45

- NaCl -0.25%

- Ph- 7.3-7.5 before sterilization

- Streptomycin yields in production fermenters respond strongly to high aeration and agitation.

- Optimum temperature 25-30°C.

- Optimum pH range from 7 and 8.

- Fermentation lasts approx. five to seven days.

- Streptomycin yields probably in excess of 1200 mg per milliliter.

A commercial streptomycin fermentation is mainly passes through the three phases:

-

- Phase I

- Phase II

- Phase III

Phase 1

- Lasts approx. 24 hrs. With rapid growth during this period, producing most mycelium for the fermentation.

- Strong proteolytic activity of nutrients of S. griseous release ammonia to the medium from soybean meal and Carbon are utilized for growth.

- PH approx. 6.7 to 6.8 or 7.5

Phase 2

- Streptomycin produced at very fast rate.

- Lasts approx. 24 hrs. to 6-7 days of incubation.

- No mycelial growth.

- Ph approx. 7.6 to 8.

- Ammonia is utilized and glucose is rapidly withdrawn from medium.

Phase 3

- In this phase, sugar has been reduced from the culture and the production of streptomycin stopped.

- The cell lyses and releases ammonia and PH rises.

- Fermentation is harvested before start of this phase.

Harvest and Recovery

- When fermentation is completed, by using the filtration technique mycelium is segregated from the broth.

- In one procedure, the streptomycin is adsorbed from the broth onto activated carbon and hence eluted from the carbon with dilute.

- Then passes through column containing cation exchange resins to adsorb streptomycin from the broth.

- Column is washed with water.

- Streptomycin is eluted with HCL before concentration resins in to adsorb streptomycin from vacuum almost to dryness.

- In methanol streptomycin is dissolved and then it was filtered.

- Addition of acetone to the filtrate for the precipitation of the antibiotic.

- Finally, precipitate of antibiotics is washed with acetone and then dried.

- Mixed in methanol for preparation as the pure streptomycin calcium chloride complex.

Uses

Medication

- The first line of antibiotic is Streptomycin which is utilized against the gram negative bacteria in animals such as (horse, cattle’s, sheep etc.).

Pesticides

- To fight with the bacteria streptomycin is also tried as a pesticide, which is apart from human applications.

Protein purification

- Sometimes Streptomycin sulfate is added for removing nucleic acids, when protein purifying from the biological extracts.

Reference and Sources

- 10% https://patents.google.com/patent/US2541420A/en

- 3% https://en.wikipedia.org/wiki/Streptomycin

Also Read:

- what is microbiology?

- What is Gene Expression?

- Different Types of chromatography

- Ethanol : production, recovery and uses

- Different types of Pathways for ATP Production

- Reverse Transcription Polymerase Chain Reaction (RT-PCR)

- Bacterial Growth Curve: Definition, Phases and Measurement

- Bacterial Growth Curve: Definition, Phases and Measurement

- Mutations: Introduction, Types, Causes and Repair Mechanisms

- Citric acid: Introduction, Fermentation, Recovery and Uses

- Chromatography: Introduction, Principle, Classification and applications

- Xanthan gum: Introduction, Structure, applications and production

- Biosafety Cabinet: Introduction, Development and Safety guidance

- Riboflavin: Fermentation, Harvesting and Uses

- Antimicrobial Chemotherapy: History, Characteristics and Tests

Very good articles

Thank you Nadeem

I really love to read it.

Hope, it’s worth for my work.

Thanks for this notes…

I used it for my exam preparation..

It Really helped a lot….